Interview with Brigitte Closs-Gonthier

Brigitte Closs-Gonthier, Deputy General Manager, Innovation at SILAB

SILAB

Mrs. Closs-Gonthier, SILAB is a company that researches, develops, produces and markets natural active ingredients for the cosmetic and dermo-cosmetic markets. What role do biotechnologies have in your product development?

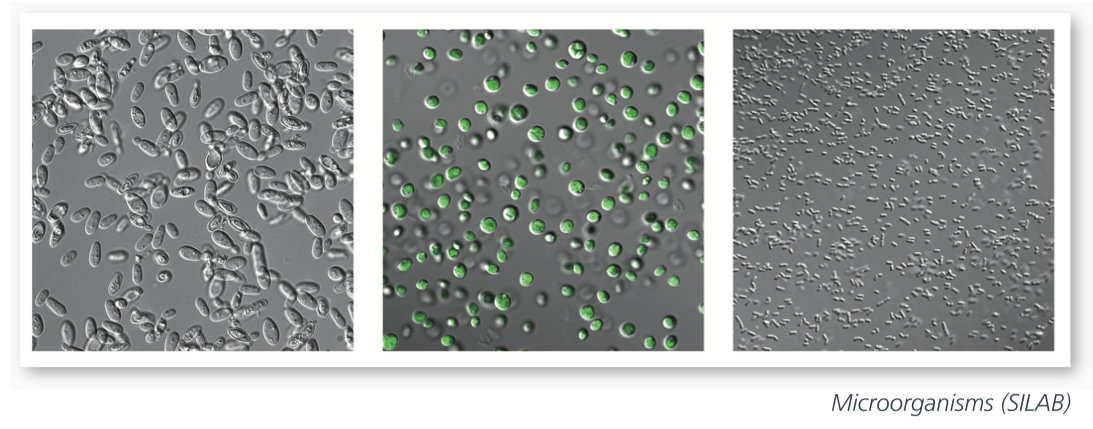

Since its creation more than 35 years ago, SILAB has been developing natural active ingredients from 100% natural raw materials. Historically, these raw materials are from plants origin. However, we detected very early the huge potential of biotechnologies (yeasts, microalgae, bacteria) as an additional source of raw materials for the cosmetics market and became one pioneer in 1999, launching our first anti-aging active ingredient obtained from a yeast. With the aim of strengthening our bio-sourcing commitment, we developed a real in-house expertise in the cultivation of microorganisms, first at the laboratory scale, then transposed at the industrial scale. To this end, and in line with our strategy of independence, we self-financed as of 2014 our own fully automated Production Unit for Biotechnologies onsite, an investment of 5 million euros.

What are the advantages of using biotechnologies? What are their characteristics?

Biotechnologies are likely to play a much larger role in the future as they can enable companies to diversify their supplies and offer additional levers to drive innovation. Indeed, they open up a wide range of possibilities as a new source of raw materials, since microorganisms have three branches (yeasts, bacteria, microalgae), each with thousands of species, compared to plants that have only one branch.

In addition, at SILAB, we place all our efforts in meeting consumers’ needs as well as market and legislation requirements for naturality, efficacy, traceability and safety. In this context, we value the use of biotechnologies, which is fully sustainable and respectful of biodiversity. It offers the opportunity to obtain, on demand, a large quantity of biomass and supernatant without using agricultural land, thus significantly reducing the ecological footprint usually related to plant crop. Only one initial sample of a strain of natural microorganisms is needed, as it can be reproduced almost indefinitely.

In addition, using biotechnologies as raw material is completely in line with our commitment to traceability and safety, as all the R&D and production phases are conducted in-house. Secure strains, qualified as Biosafety level 1 and GMO-free, are used. An external expert partner confirms their genetic identity. A quality biomass and supernatant, rigorously analyzed and validated, is obtained. It is repeatable and reproducible over time, thanks to the robustness of the processes in place.

Do you think consumers are ready to accept product derived from microorganisms?

We do think so indeed. In recent years, there has been an emerging trend related to pre-, pro- and postbiotics. The consumers first discovered these terms related to food industry and gut health. These microorganisms are now an area of research in the cosmetics industry. As a precursor company, we got interested in the idea of transposing their beneficial effects to the skin for the development of our latest active ingredient. At the crossroads of various fields of expertise (mastering natural, microbiota and biotechnologies), LACTOBIOTYL® is a natural postbiotic active ingredient specifically designed to restore hydration and luminosity to dry skin, while preserving the equilibrium of the cutaneous microbiota.

For this development, our research teams drew inspiration from the adaptation properties of a plant probiotic (Lactobacillus arizonensis) to a desert climate. This good bacterial species colonizes one of the shrubs most adapted to the extremely dry desert conditions of Arizona, jojoba. It bioconverts the molecules of its host in order to ensure its survival. Our teams have reproduced in industrial bioreactors the natural environment of this bacterial species specific to desert climates by growing it in association with its host, jojoba. This targeted bioguiding technology has led to the selective production of bioactive molecules (= postbiotics) that constitute LACTOBIOTYL®.

LACTOBIOTYL® development was clearly bioinspired. Do you consider this approach as being an important lever driving innovation?

At SILAB, we are deeply convinced that Nature already has all the answer. As a result, our products are aiming at reestablishing the homeostasis of the skin and the concepts supporting their developments are mostly bioinspired.

To provide another example, let us focus on the case of ECOBIOTYS®. SILAB studied the very particular microbiota of floral nectar, the Nectarobiota®, and more specifically the one of a refined and highly nectariferous plant (Hoya carnosa or porcelain flower), which ensures its defense, development and regeneration. Within this Nectarobiota®, we performed a customized sampling and specifically isolated the yeast Metschnikowia reukaufii to use it as a raw material for the development of our novel active ingredient able to rebalance the microbiota of mature skin and revive complexion radiance: ECOBIOTYS®.

For the first time in the cosmetics industry, natural molecules were extracted from the microbiota of plants to influence the skin microbiota. This unprecedented bio-inspired approach resulted in three awards for ECOBIOTYS® (the 1st prize at PCHi 2019, the Gold award at in-cosmetics Asia 2019 and the Bronze award at in-cosmetics Global 2019), which is a true recognition that bioinspiration leads to innovation.

Biotechnologies will account for a growing part in the cosmetics industry. What are the perspectives?

These two examples perfectly illustrate that biotechnologies are fully integrated in SILAB’s product development strategy, combined with many other fields of expertise. For the moment, 16 active ingredients out of our standard catalogue of around 100 actives are coming from biotechnologies. In order to meet the growing need of the market, we are already extending our production capacity, multiplying it by 4 with a new production unit.