BIO-based SURFACTANTS

Interview with Tim Kraemer, Director, Global Business Development and Megan Hopkins, Marketing Manager at

Locus Ingredients

Can you explain the difference between Biosurfactants and bio-based surfactants?

We have a great blog article on exactly this topic that I will paraphrase below. The full article can be found here: https://locuspi.com/learning-center/bio-based-surfactants/

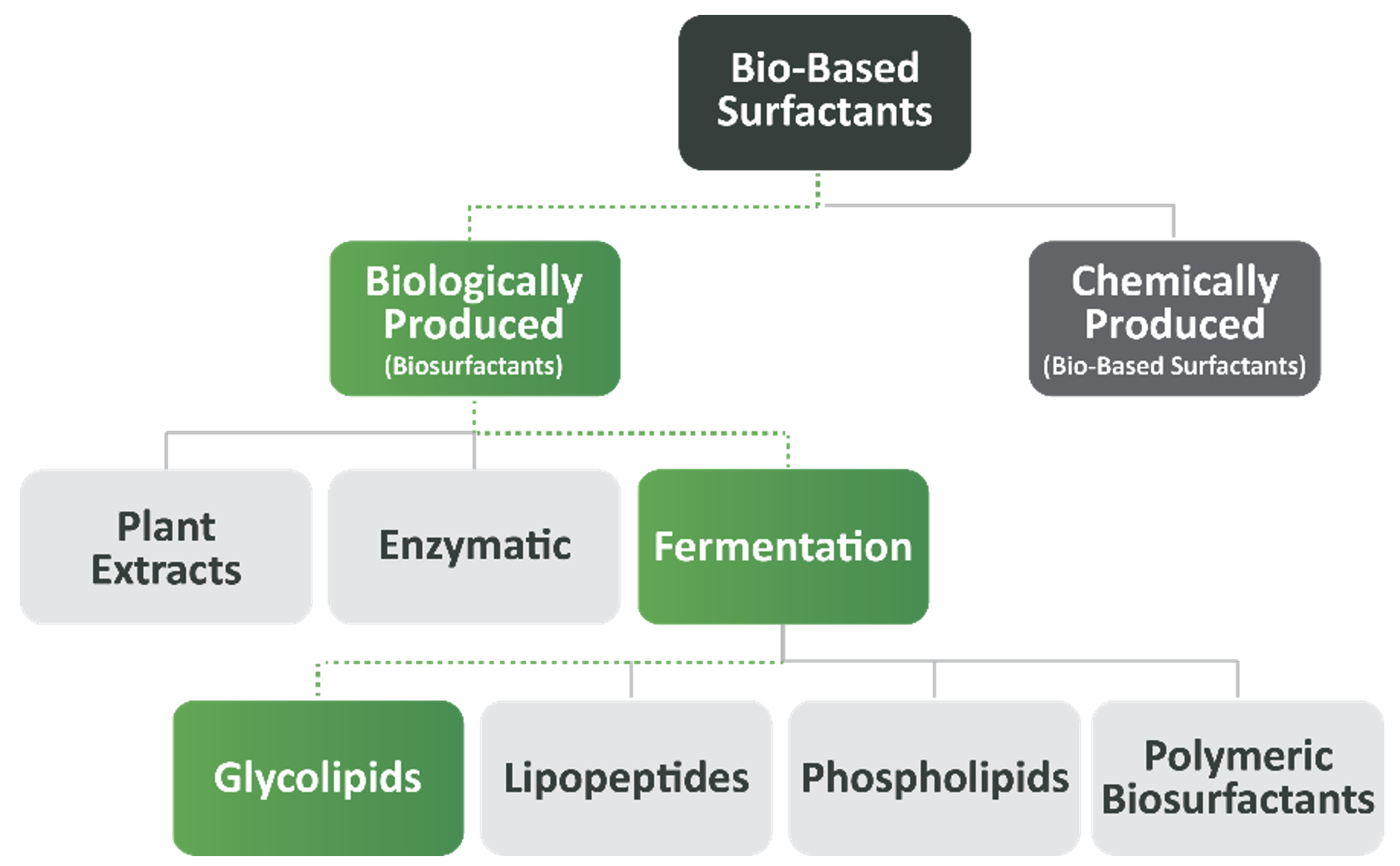

Biosurfactants are a type of bio-based surfactant produced naturally—often through fermentation. Unfortunately, some manufacturers refer to their bio-based surfactants as biosurfactants, further confusing the terminology. It’s important to note that all biosurfactants are bio-based surfactants, but not all bio-based surfactants are biosurfactants.See the chart below for a visual breakdown:

There are two key differences between bio-based surfactants and biosurfactants that end users may not realize:

- The bio content

- Biosurfactants are 100% biobased and made from agricultural raw materials

- Bio-based surfactants considered “wholly biobased” can contain up to 5% carbon from fossil fuels and can be made from non-renewable raw materials

- How the surfactant is produced

- Biosurfactants are biologically produced; Locus Ingredients’ biosurfactants specifically are fermentation produced using renewable raw agricultural materials

- Bio-based surfactants can be chemically produced

Based on these two factors, biosurfactants—specifically fermentation-produced biosurfactants—have proven sustainability and performance advantages compared to bio-based surfactants.

More details:

Bio-based surfactants - The USDA defines bio-based surfactants as those that are derived “… in whole or significant part of biological products or renewable domestic agricultural materials (including plant, animal, and marine materials) or forestry materials.” In short, all bio-based surfactants are created at least in part from bio-based, renewable feedstocks and raw materials.

- Some bio-based surfactants are chemically produced- Manufacturers of bio-based surfactants advertise their products as a sustainable alternative to traditional surfactants. However, the production of many bio-based surfactants requires traditional chemical reactions. These reactions consume substantial levels of heat and electricity generated by hydrocarbon sources—leaving a larger carbon footprint. For example, many key manufacturers in the global biosurfactant market produce alkyl polyglucosides (APGs) and glucamides—well-known bio-based sugar surfactants—at an industrial scale. Both APGs and glucamides are developed using renewable starting materials (such as glucose, fatty alcohols, and triglycerides). However, like conventional surfactants, both ingredients are synthetically produced using chemical reactions. By developing their bio-based surfactants using processes that require fossil fuels, the sustainability claims of many manufacturers are negated.

- Bio-based surfactants are not always 100% biobased- Bio-based surfactants can contain carbon derived from fossil fuels. Classifications have been developed to rank bio-based surfactants based on their starting materials. Two examples include:

- The Renewable Carbon Index (RCI), which grades bio-based surfactants based on their bio content, or the percentage of total carbon derived from plant or agricultural-based sources as opposed to carbon from fossil fuels.

- The European Commission of Standardization (CEN), which classifies surfactants into four categories based on the percentage of renewable carbon (carbon derived from renewable feedstocks) that they contain.

Classifications like these allow surfactants to be categorized as fully bio-based even if they contain fossil-fuel based materials. For example, CEN considers a surfactant “wholly bio-based” as long as it contains more than 95% renewable carbon.

Biosurfactants - Biosurfactants are bio-based surfactants that contain only bio-based, renewable feedstocks AND are produced using sustainable, non-chemical processes. This means the bio content of biosurfactants is 100% renewable carbon. It also means that unlike chemically produced, bio-based surfactants, biosurfactants are produced directly from biological processes of microorganisms. Biosurfactants can be produced from a variety of organic materials, and they are typically classified by their molecular structure—with varying degrees of complexity. In short, both the formulation and production of biosurfactants includes fully renewable materials with no hydrocarbon-reliant chemical reactions.

What are the challenges of bio-based surfactants in the market?

We see three key challenges of bio-based surfactants in the market:

- Confusion on bio-based surfactants vs. biosurfactants

- One of the biggest challenges is what was addressed in question one—industry confusion on the difference between bio-based surfactants and biosurfactants. We are working to educate the industry on the differences to help formulators make informed decisions when selecting a bio-based surfactant.

- Lack of biosurfactant supply

- Another challenge is manufacturing capacity to meet growing biosurfactant demand. There are few companies globally that can manufacture fermentation-produced biosurfactants. These specific biosurfactants have been studied for decades and validated as one of the most promising green ingredients to replace surfactants. However, in the past costly production methods with limited volume capacities restricted their broad use in product formulations.

- Locus Ingredients’ innovative biomanufacturing technology solves these challenges, enabling the development of high-performance biosurfactants at a commercial scale. Our methods produce biosurfactants with higher productivity at a fraction of the production time of traditional fermentation processes.

- The modular platform can be scaled rapidly and has an extremely low carbon footprint. Using this proprietary production approach, Locus Ingredients has successfully optimized the creation of multiple INCI and TSCA-approved biosurfactants with unique properties at significantly lower costs.

- Understanding biosurfactant use in formulation

- Bio-based surfactants as a category and specifically biosurfactants are a new technology for formulators. There are often questions on their properties and how to formulate with them, including whether they can used as a direct replacement or reformulated as a co-surfactant.

- To help streamline formulation, our science team assists formulators in selecting the appropriate biosurfactant with mechanisms of actions needed for a specific product application. We have also developed a library of ready-to-use formulations for common personal care, household and industrial products. These formulations feature biosurfactants and other synergistic ingredients, which have been tested for efficacy.

What are some claims producers can make when formulating with bio-based surfactants?

The claims producers can make depends on the specific bio-based surfactant being used, its approvals and certifications, and the region where the product is being sold. Many bio-based surfactant suppliers advertise their products as providing an environmentally sustainable alternative to conventional surfactants. But not all bio-based surfactants are created equal. Only biosurfactants minimize environmental impact from production to end use while delivering proven performance gains for CPG and industrial suppliers.

Formulators using Locus Ingredients’ sophorolipids, a type of biosurfactant in the glycolipid class, can make a multitude of claims:

- 100% bio-based

- The biosurfactants have earned the USDA Certified Biobased Product labelfor containing 100% bio-based, renewable content.

- Safer Choice product label

- The biosurfactants are also on the EPA Cleangredientslisting with direct release approval, meaning they can be used in products with the EPA Safer Choice label—including products with direct release into waterways.

- No Prop 65 or other warning labels

- The biosurfactants have no 1,4-dioxane, EO, formaldehyde or other harmful trace chemicals—meaning formulations don’t have to include any Proposition 65 or other warnings.

- Clean-label, sustainable ingredients

- The biosurfactants also have EU REACH registrationand TSCA certification which streamlines use as a sustainable ingredient across multiple regions and product categories.

How do bio-based surfactants compare to surfactants from fossil source?

Locus Ingredients’ sophorolipid biosurfactants are high-performance, sustainable alternatives to bio-based and traditional petrochemical-based surfactants. These biosurfactants offer unique advantages. What sets these specific biosurfactants apart is their multifunctionality and complex molecular structure. They have low CMC and effective surface tension reduction. This results in lower use rates and lower in-use cost without sacrificing performance.

The high activity of these sophorolipids can solve a multitude of formulation pain points, including:

- Replacing or minimizing the use of petrochemical surfactants

- Replacing palm oil-based surfactants

- Minimizing toxicity

- Maximizing biodegradability

- Providing equal or better product performance

- Reducing the carbon footprint

Each biosurfactant ingredient from Locus Ingredients is tailored for use in a multitude of applications, with better performance, lower toxicity, and a significantly better carbon footprint than fossil fuel-based surfactants.

Do bio-based surfactants really reduce the carbon footprint significantly?

The answer depends on the type of bio-based surfactant being used. When looking at Locus Ingredients’ biosurfactants, there are four key elements that lower the carbon footprint on a cradle-to-grave basis:

- 100% renewable carbon from raw materials

- The largest impact on carbon footprint on a cradle-to-gate basis is that our natural raw materials are 100% renewable carbon grown in field crops.

- High-efficiency production

- The next biggest savings is our production process, which includes circulate use of process water, renewable energy sources and relative lower conversion need for heat, steam and vacuum when compared to traditional synthetic chemistry. Increased availability of renewable power sources will add additional improvement to our total footprint in the coming years.

- Locally sourced materials

- Most raw materials and biomass are regionally sourced. New enhancements will deliver raw materials closer to our manufacturing plants and further decrease shipment distances to our customers as we expand.

Biosurfactants from Locus Ingredients lower the environmental impact and carbon footprint of household, commercial and industrial products by replacing a broad range of functionalized surfactants, meeting ingredient disclosure regulations, and minimizing human and aquatic toxicity and health concerns. The ingredients contain zero 1,4-Dioxane, are not ethoxylated and free of formaldehyde with no Prop 65 chemicals. The use of Locus Ingredients’ biosurfactants can also help reduce or eliminate the household and commercial products industry’s dependence on ingredients derived from palm oil which solves critical issues associated with palm oil usage, such as deforestation, disappearing wildlife habitats and abusive labor practices during harvesting.

What are typical applications for bio-based surfactants?

Bio-based surfactants can be used in a multitude of applications across almost every global sector. Locus Ingredients produces commercial volumes of biosurfactants, specifically sophorolipids (SLP), that are used globally in industrial and CPG applications including:

- Personal care products, such as lotions, shampoos, makeup removers, etc. (available through Dow)

- Home care products (available through Dow) like all-purpose cleaners, glass cleaners, carpet cleaners, detergents, car and power washes, etc.

- Industrial and institutional versions of those cleaning products (I&I)

- Paints, coatings, adhesives, sealants and elastomers (C.A.S.E)

- Metalworking fluids

- Agricultural surfactants & adjuvants

- Industrial applications like water treatment, pulp & paper, and textile & leather

About Locus Ingredients

Locus Ingredients (Previously known as Locus Performance Ingredients®) is an award-winning green tech dedicated to developing environmentally friendly biosurfactant solutions that replace legacy surfactants and eliminate regulatory challenges in CPG and industrial markets. Using advanced, modular fermentation technology with a low carbon footprint, the team creates performance-driven, sustainable ingredients that are USDA certified as 100% biobased and non-GMO, with no palm oil, Proposition 65, EO, formaldehyde or other trace chemicals. Each multifunctional ingredient can be used in a multitude of personal care, household and industrial applications, with low usage rates, superb multifunctionality and superior performance. Locus Ingredients gets its core scientific capabilities from its parent company, Locus Fermentation Solutions (Locus FS), an Ohio-based, globally recognized biosurfactant company. For more information, visit LocusIngredients.com.