What Changing Regulations and Consumer Preferences Mean for Global Sun Care Brands

Interview with Kristie Ford

Director, Sun Care Solutions, Hallstar

Daily sunscreen use is a growing imperative for many beauty consumers who recognize the damaging effects of sun exposure without the use of effective UV filters. We are reading more than ever about sun care safety in the news, but the focus has broadened to include the safety of the filters themselves – for users as well as for the environment. What does that mean for brands?

Sun care brands are looking for solutions to meeting performance requirements in the face of increasing regulation. With the recent banning of traditional UV filters like oxybenzone, oxycrylene and octinoxate from sunscreen formulation, developers have more limited ingredient options, especially if they want to create high SPF products with pleasant sensoriality at a reasonable price. And as sun care is often considered daily wear now, many users are looking for product multifunctionality as a way to simplify their skin care regimen.

Consumers are gravitating towards healthier lifestyles, and they’ve become more mindful of the products that they’re using, including their sun care products. They are questioning ingredients, looking for formulations that they can feel good about using.

In light of this, consumers may seek out ‘natural’ indicators in terms of label claims or ingredient lists to determine if those products satisfy their own standards. But the definition of ‘natural’ sun care can vary broadly – to some, it means helping preserve planetary biodiversity; for others, it might be about ingredients that are safe for sensitive skin.

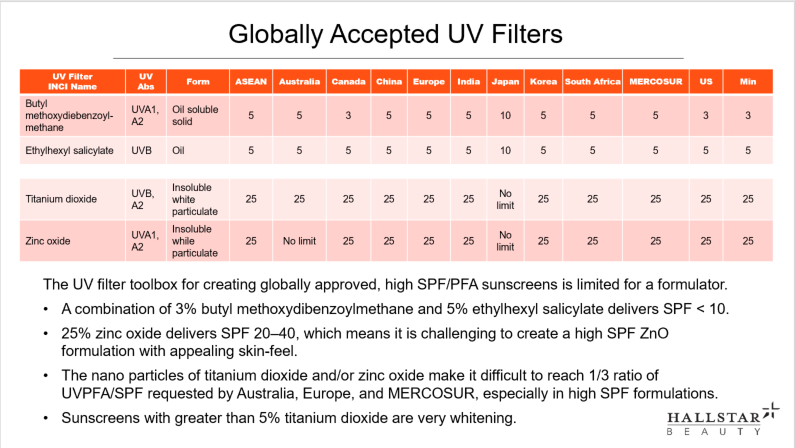

To meet the demand and comply with regulations, many sun care formulators and brands are turning towards the use of mineral UV filters such as zinc oxide or titanium dioxide because they’re perceived as safer on both consumer and environmental health.

What is your opinion? Are mineral sunscreens really safer than organic sunscreens?

Hallstar pioneered photostability science – the measurement of a sunscreen formulation’s skin absorption before and after irradiation. When assessing safety and effectiveness, it’s important to look closely at the stability of organic vs inorganic (mineral) filters.

Organic UV filters are a group of carbon-containing compounds designed to absorb UV radiation. To maintain effectiveness over time, they should not alter chemically after repeated UV irradiation. However, many common organic UV filters, when they absorb UV radiation and enter their excited states rich in energy, are often unable to quickly release the excited state energy to return to their ground state where they are stable and ready to absorb additional UV energy. These unstable UV filters will thus photodegrade over time in the sun, losing their absorption capability and generating photoproducts that have not been studied for their safety on human skin.

An example of such a UV filter is avobenzone (INCI: Butyl Methoxydibenzoylmethane). While a very common and globally-approved UVA filter, it is notoriously unstable under UV radiation. Hallstar was one of the first companies to discover the photodegradation of avobenzone and dedicated many years of research to developing a range of solutions to stabilize it. The result was cutting-edge photostabilization products such as SolaStay® S1, SolaFresh™, Polycrylene®, and the China-compliant photostabilizer AvoBrite®.

Inorganic UV filters, on the other hand, are a group of mineral oxides such as titanium dioxide (TiO2) and zinc oxide (ZnO). They are often referred to as physical filters, as compared to chemical filters which are organic compounds. There is a common misconception that inorganic filters only reflect, scatter and refract sunlight so they are safer to our skin than organic filters. In fact, both titanium dioxide (TiO2) and zinc oxide (ZnO) are semiconducting materials capable of absorbing UV energy, which contributes most of their UV shielding ability. After absorbing UV energy, these mineral particles are promoted to their conducting band and become photoactive.

When photoactivated by UV light, TiO2 and ZnO generate highly oxidizing radicals such as -OH, and other reactive oxygen species (ROS) such as H2O2 and singlet oxygen, 1O2, which are known to be cytotoxic and/or genotoxic. Therefore, inorganic sunscreens commonly used in today’s market convey a false sense of security to the consumers.

From Hallstar’s perspective, organic and inorganic filters can be equally safe if formulated with proper photostabilizer and functional ingredients, and if they are used appropriately by the sunscreen user. This last point is an important one. The most effective sunscreen is the one that consumers are actually going to want to wear and reapply every day.

So, what do you recommend brands do to encourage consistent use of effective sunscreens?

If the formulation and format of a sun care product delivers a pleasant application experience and is well-received by consumers, that product is likely to be applied (and consistently re-applied) more often – which increases the chances of adequate sun protection.

The same attention to consumers’ sensory reactions in other personal care products is also evident in the sun care space and certainly the pandemic has reinforced these goals because people are seeking feel-good formulations and self-care options during stressful times.

While consumers are seeking out natural products, they are not willing to sacrifice aesthetics. The top aesthetic concerns cited by consumers leading to under-use of sunscreens are transparency and skin-feel. And one of the most common concerns associated with mineral-based sunscreens is the white cast that’s left on your skin after application. Zinc oxide is often sought after as a mineral UV filter because it provides UVA and UVB protection, it’s globally acceptable, and it has a lower refractive index than titanium dioxide – and this means that it’s going to be the more transparent option of the two by weight.

The limitation with zinc oxide is that the use level needs to be fairly high – about 20-25% percent – to achieve an SPF of 20 to 40. And even though zinc oxide is more transparent than titanium dioxide, formulators will need to combat whitening and a chalky skin-feel at this high a use-level. One way to reduce whitening is to reduce the level of zinc oxide, but because zinc oxide is a UV filter, decreasing its level in formulation will decrease the sun protection efficacy.

Hallstar found a solution for improving the level of sun protection with a reduction of zinc oxide when it launched

SolaPure™ Glo, a nature-derived multifunctional emollient inspired by turmeric. This ingredient leverages the phytoconstituents present in turmeric to promote overall skin health while also allowing formulators to achieve similar SPF and PFA performance with a reduction of zinc oxide when used in minerals sunscreen systems. This solution not only aims to improve the transparency but also enhances the skin-feel during consumer application.

Yes, consumers want effective UV protection but it’s critical that their sun care formulations spread smoothly, deliver a pleasant skin feel, dry smoothly, and don’t cause whitening. This is becoming increasingly important as sun care is no longer limited to beachwear and UV filters are more commonly integrated into daily wear skin care products – part of a holistic, preventative approach to address signs of aging for healthier skin. It’s reasonable to expect that formulations with improved aesthetics help encourage consumers to apply more product. That product then has a better chance to perform at the SPF level on its label.

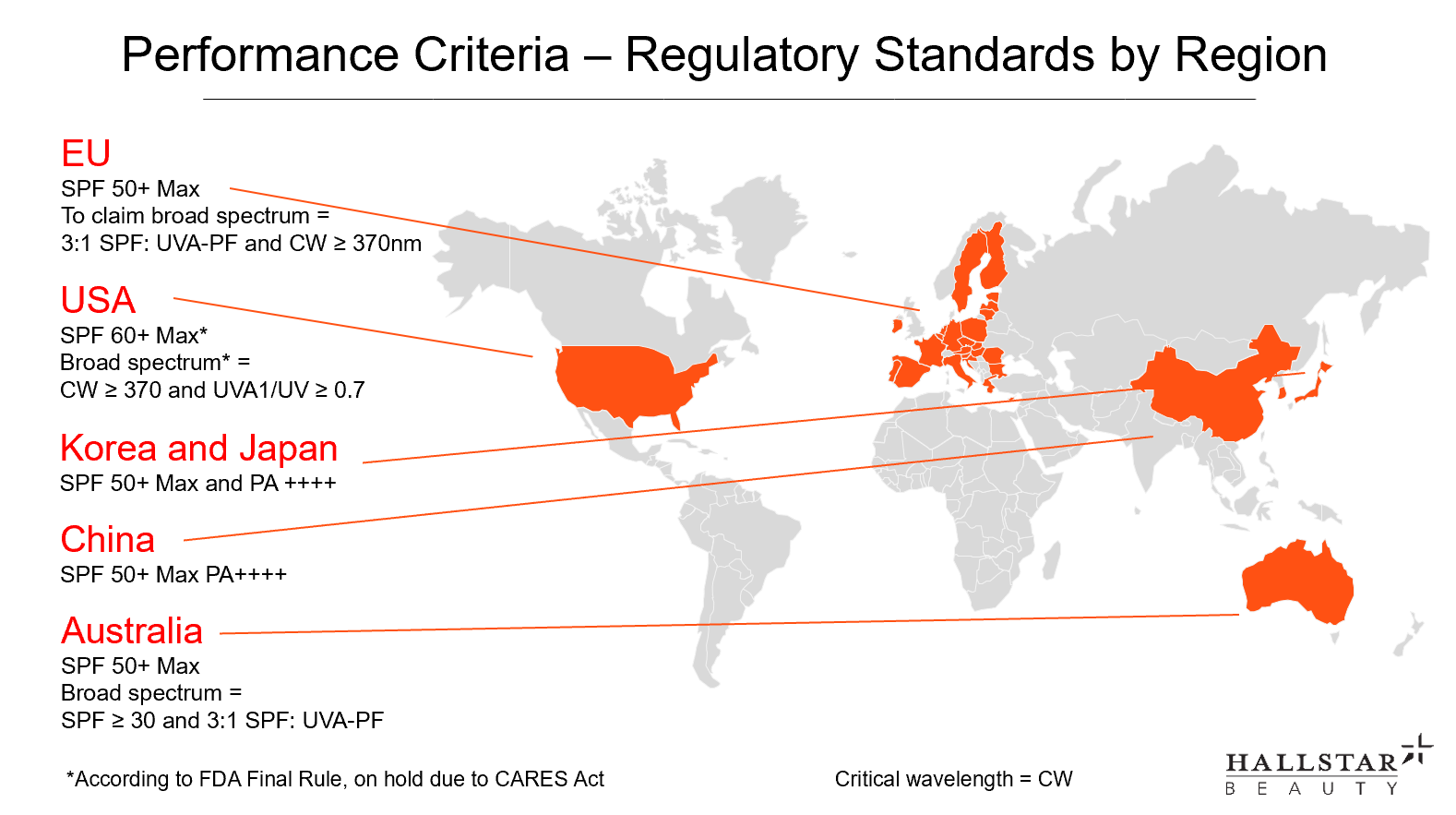

What country-specific features are there to consider in the production of sunscreens?

Individual countries have strict regulations around which UV filters can be used in sunscreen products. A product using a banned filter will not be available for purchase in that country – a major consideration for global brands. Even permitted filters may be regulated in terms of formulation percentage. In European countries, for example, homosalate can be used in body sunscreens as a UV filter agent but at no more than 0.5%, and in facial applications at a maximum of 7.34%.

A country’s regulation may also dictate minimum or maximum SPF/PFA levels.

Finally, consumers in different global regions have preferences for sun protection aesthetics. In some countries, a whitening effect is more acceptable than in others. Asia-Pacific sunscreen users want their sunscreens to have an even lighter feel than the typical user in other areas of the world.